Have you ever wished your factory floor could just tell you what was wrong? That an enormous, high-precision industrial asset could tap you on the shoulder and politely murmur, “You know, I’m feeling a bit peaky; I might throw a bearing in a fortnight”? It sounds like the kind of delightful, slightly absurd scenario we’d all conjure up on a Friday afternoon, but with Siemens’ formidable implementation of artificial intelligence, particularly through their Senseye platform, you’ll find that we’ve stepped firmly into the realm of the pragmatically possible. This isn’t just incremental progress; it’s a tectonic shift in how we conceive of industrial uptime.

The Vexed Question of Machine Mortality

Let’s dissect the core of what they’ve done, shall we? This is where the technical meat is, and frankly, it’s a magnificent piece of engineering.

At its most granular level, the system relies on a dense network of sensors strategically placed across factory equipment. Let me be clear: these aren’t your grandfather’s pressure gauges. My own grandfather was a brilliant oilfield mechanical engineer, a man who could tell you more about the health of a pump just by the sound of it than most modern diagnostics. But even his keen intuition and trusty analog dials simply couldn’t compete with the microscopic data resolution these new sensors provide. They’re continuously collecting real-time operational data, monitoring everything from microscopic vibration anomalies to minute temperature fluctuations. We’re talking about a torrent of data so immense it would make a traditional human analyst weep.

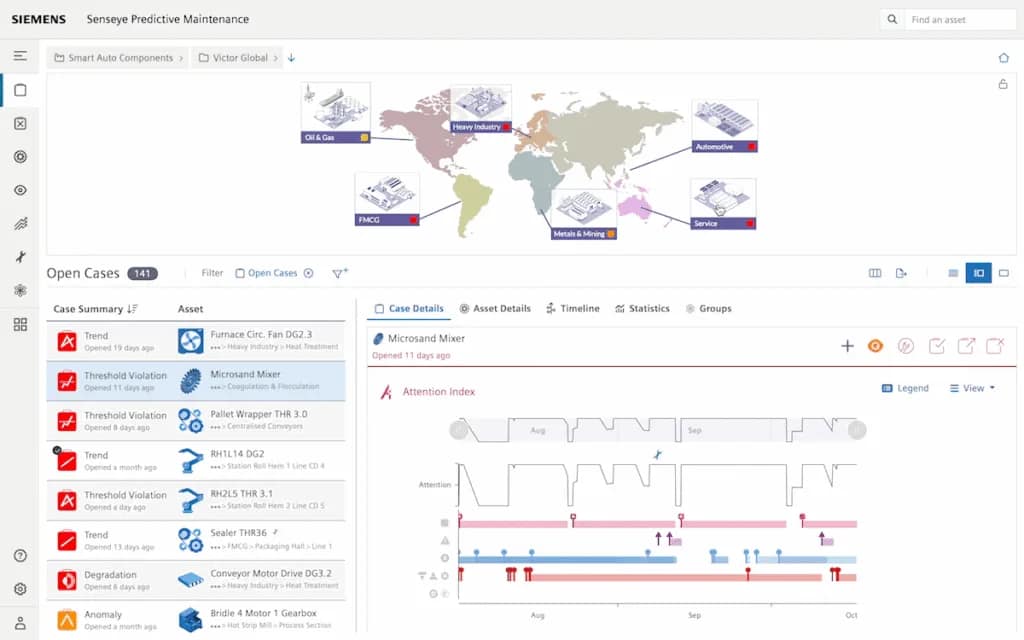

Enter the Senseye AI platform. This is where the genuine computational alchemy happens. The massive stream of data flows into the platform, which subjects it to advanced machine learning and generative AI algorithms. The system doesn’t just flag immediate problems; it hunts for precursors—those subtle, emergent patterns that foretell a catastrophic event. It’s essentially an industrialized prognosticator, predicting equipment failures weeks in advance, long before any obvious, physical manifestation of distress.

Why is this so consequential? Because foreseeing potential breakdowns allows for maintenance to be scheduled proactively, not reactively. You’re no longer scrambling for parts, enduring costly downtime, and footing the bill for emergency repairs; you’re engaging in a precise, surgical intervention. That proactive approach isn’t merely sensible; it’s an economic imperative.

A Dialogue with the Assembly Line: The 2025 Update

The computational bedrock of Senseye has been significantly augmented with a pivotal 2025 update: the introduction of generative AI and conversational interfaces.

If the underlying machine learning was about prediction, this new layer is about democratizing insight. Maintenance teams don’t have to navigate labyrinthine dashboards or learn arcane query languages anymore. They can simply interact with the platform through natural language. You’re essentially asking the machine, in plain English, a highly technical question.

- “What’s wrong with Line 2?”

- “Have we seen this specific vibration pattern before?”

The generative AI doesn’t just retrieve local data; it draws on a global maintenance dataset, learning from millions of cases across disparate industries and geographies. This system is teaching itself, constantly improving its diagnostic acumen, which is frankly a breathtaking prospect.

Of course, with sensitive industrial data, security is paramount. You don’t want a critical infrastructure asset broadcasting its operational secrets to the ether, do you? Siemens has assured that the AI operates within secure private cloud environments, with strict data protocols ensuring sensitive industrial data remains perpetually protected. It’s a closed-loop system of profound intelligence.

This innovation is being driven globally, too. Siemens launched a new Global AI Manufacturing Tech R&D Center in Canada, focusing specifically on leveraging AI to enhance quality and recycling processes in battery and electric vehicle production. It’s a concerted effort to push toward “adaptive production,” where factories don’t just run—they optimize themselves in real time.

The Undeniable Balance Sheet Benefits

The results of this technological deployment are more than just theoretically advantageous; they are quantifiably staggering.

For those of us familiar with the classics—and I’m talking about the essential business scripture, Eliyahu Goldratt’s The Goal—you’ll immediately appreciate the profound impact here. This AI is identifying and neutralizing the ultimate bottleneck: unscheduled machine downtime. By attacking this constraint with surgical precision, the entire system’s throughput is optimized. Unplanned outages, the true nemesis of the manufacturing world, have been cut by 30–50%. Furthermore, pilot projects are reporting a saving of 25% in reactive maintenance time. It’s a genuine testament to the predictive power of the system.

This increased prescience offers a cascade of benefits that ripple out across the entire enterprise:

- Maximized Staff Efficiency: Maintenance workflows are streamlined. The AI notifies workers only when intervention is truly needed, effectively eliminating unnecessary, time-consuming check-ups. Staff can dedicate their time to high-value, scheduled work.

- Enhanced Quality Control: The very same sensors and AI tools are capable of detecting minute product defects that even the most meticulous human inspector might miss, bolstering consistency and dramatically reducing waste.

- Enterprise-Wide Optimization: Automated diagnostics, resource optimization, and improved inventory and supply chain logistics benefit the enterprise whole. It’s an interconnected web of efficiency.

It’s a marvelously scalable solution as well; Siemens offers packages that work just as effectively for a smaller regional site as they do for colossal global operations housing thousands of connected machines.

The Arduous Path to Adaptive Production

Now, we wouldn’t be having an honest, technical discussion if we didn’t acknowledge the inevitable friction that comes with such fundamental transformation. This hasn’t been a walk in the park.

Integrating this level of advanced AI with legacy machinery required complex engineering and significant system overhauls. You can’t just plug a 2025 AI platform into a 1990s machine and expect immediate communion; it necessitates thoughtful, often recalcitrant integration work.

There was also the entirely predictable, yet no less critical, issue of workforce resistance. Siemens proactively addressed this by investing heavily in training and digital skills, ensuring that staff were not replaced, but rather enabled to leverage the new AI-driven tools. It’s an important distinction: the system is an augmenter of human expertise, not a usurper.

Siemens’ AI-powered predictive maintenance isn’t just an intriguing case study; it’s a benchmark for what industrial transformation truly looks like. It saves money, boosts productivity, and streamlines operations with an elegance that points the way to a future of genuinely intelligent, adaptive manufacturing.

0 Comments