Do you ever think about the sheer, mind-boggling complexity of a modern aircraft engine? We’re talking about a multi-ton behemoth of metal, ceramics, and composites, screaming along at tens of thousands of revolutions per minute while withstanding temperatures hot enough to melt lesser materials. It’s a testament to human ingenuity. But as these engines grew more sophisticated, so too did the problems they presented, particularly when it came to maintenance. An unscheduled repair could cost an airline millions, and a breakdown was a logistical and financial nightmare.

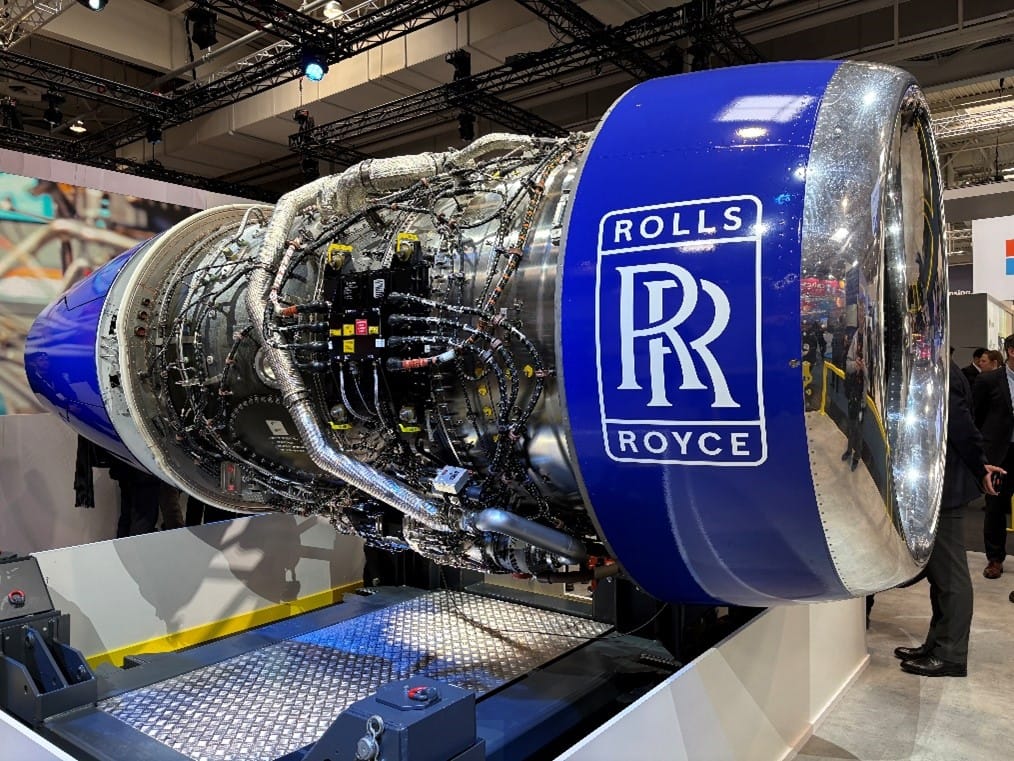

This is precisely the conundrum that Rolls-Royce, a company with a long and storied tradition of engineering excellence, had to solve. Their solution wasn’t a better wrench or a new alloy. It was something far more abstract and elegant: the digital twin.

What Exactly Is a Digital Twin?

At its core, a digital twin is a detailed, dynamic, and virtual doppelgänger of a physical thing, a living ghost of a machine. It’s a construct that mirrors the real world in real time, continuously slurping up data from IoT sensors, running complex simulations, and using AI to predict outcomes. Think of it as a meticulously crafted marionette, with the physical engine as the puppeteer, pulling the strings and bringing its digital counterpart to life.

For Rolls-Royce, this meant equipping their IntelligentEngine program with hundreds of sensors. These aren’t just thermometers and pressure gauges; they’re constantly tracking things like vibration, fuel usage, and the subtle stresses on each component as the aircraft flies. This torrent of data is then fed into a sophisticated simulation, creating a digital twin that doesn’t just look like the engine—it behaves like it.

The Digital Twin in Action: From Reactive to Predictive

The true genius of this approach lies in the shift from a reactive to a predictive paradigm. Historically, engine maintenance was a scheduled affair, with inspections happening at fixed intervals, or a reactive scramble after a problem had already reared its ugly head. Imagine you’re a long-distance train conductor. Traditionally, you might just wait until a wheel starts wobbling or a brake pad wears through—potentially causing a major disruption or even a derailment. Wouldn’t it be better if you had a system that could tell you, months in advance, that a specific section of track was causing undue stress on your wheels, allowing you to schedule a replacement during a stopover far from any potential mishap?

Rolls-Royce flipped this on its head. Their digital twins, powered by AI, analyze the incoming sensor data for anomalies, spotting subtle patterns that a human eye would likely miss. This lets the system forecast when a specific component might fail, enabling the airline to schedule maintenance precisely when it’s needed, not a moment before or a moment after.

This isn’t just about catching problems early. It’s a holistic approach that changes everything:

- Reduced Downtime: Airlines can keep their fleets in the air longer, scheduling maintenance during planned layovers rather than having a plane grounded unexpectedly.

- Lower Costs: Fewer emergency repairs and longer component lifespans translate directly to the bottom line, saving millions for Rolls-Royce and its customers.

- Enhanced Safety: The ability to catch and address potential faults before they become a real-world threat elevates safety standards to a new level.

A Story of Innovation and Collaboration

The Rolls-Royce digital twin program wasn’t a sudden, grand announcement. It began as a necessity, a direct response to the high costs and logistical complexities of modern aviation. It required a significant culture shift, moving a historically hardware-centric engineering firm toward a model where software, data, and analytics were equally paramount.

This wasn’t the work of one lone genius. It was a cross-disciplinary undertaking that brought together aerospace engineers, software developers, data scientists, and operational specialists. They had to speak a common language, bridging the gap between the mechanical world of turbines and the algorithmic world of AI. That collaboration, more than any single technological breakthrough, is what made this project a success.

How They Did It: A Look Behind the Scenes

The development of the Rolls-Royce digital twin was a multi-year, company-wide transformation. It was a rigorous and coordinated effort that involved a number of key stages:

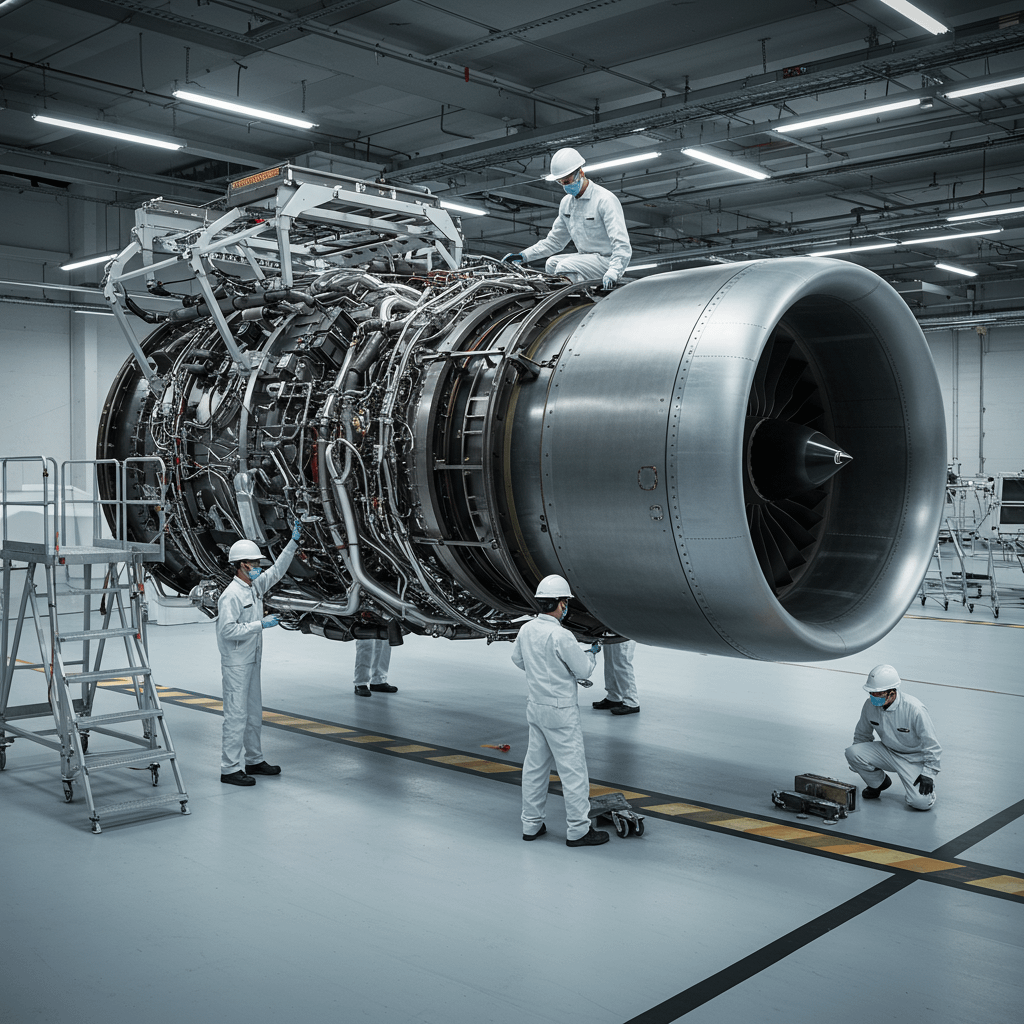

- Collecting the Data: The journey began with a physical transformation of the engines themselves. Engineers outfitted each one with hundreds of IoT sensors, meticulously tracking everything from temperature and vibration to fuel efficiency and component stress. This created a torrent of real-time data from every flight.

- Building the Virtual Twin: That data, once streamed back to Rolls-Royce’s ground systems, became the lifeblood of the project. Specialized simulation software created a real-time virtual model of each specific engine. These models were the digital twins, updating continuously as new information arrived.

- Applying AI and Analytics: With the data flowing and the twins built, the next step was to make sense of it all. Artificial intelligence and machine learning algorithms were applied to this immense influx of data. These algorithms were trained to spot the most subtle anomalies and forecast failures before they ever had a chance to happen. Over time, as the models ingested more and more information, they learned and became ever more accurate.

- Interdepartmental Collaboration: The development demanded tight collaboration. Systems engineers worked to ensure sensor integrity and data fidelity, software developers built the digital backbone, AI specialists trained the predictive algorithms, and operational experts validated the maintenance recommendations. This tight-knit partnership was the real secret sauce.

- Evolving the System: What started as a static digital replica of an engine quickly evolved into a living, adapting model. Feedback from data scientists, engineers, and frontline technicians ensured it was continuously learning and adapting to changing conditions and new engine models.

The entire initiative took several years to move from concept to commercial deployment, with early prototypes emerging in the early 2010s and reaching widespread operational use in the late 2010s. The continued partnership across these disciplines inside Rolls-Royce is a standout reason the project not only succeeded, but set a new standard for predictive maintenance and operational efficiency in aerospace.

So, Where is it Now? The Future of a Ghost Engine

So, what became of this ambitious project? The Rolls-Royce digital twin has shifted from a pioneering experiment to an industry-defining platform.

As of 2025, it’s a routine, operational cornerstone of their aerospace business. The twins are now an integral part of daily operations, powering real-time monitoring and predictive maintenance for a broad fleet of engines, including the Trent 1000, Trent 7000, and Trent XWB families. The platform, which is now a mature product, combines that IoT sensor data from thousands of engines around the globe with advanced AI, allowing the system to simulate, predict, and optimize performance with an ever-increasing degree of precocity.

The benefits are well-documented:

- Massively reduced downtime and maintenance costs.

- Improved fuel efficiency and lower emissions.

- Accelerated development cycles for brand new engine models.

And it doesn’t stop there. While its core achievement is in aerospace, Rolls-Royce is already applying the same digital twin principles to their manufacturing, marine, and energy sectors. They’ve also fostered crucial partnerships, such as with Trax for seamless MRO (maintenance, repair, overhaul) data integration, creating a simple, plug-and-play maintenance solution for their customers.

Looking ahead, Rolls-Royce is poised to push digital twin innovation even further. We’re talking about more immersive AR/VR tools for technicians, as well as the creation of “enterprise twins” that simulate and optimize entire operational, regulatory, and even environmental strategies. This isn’t just about fixing an engine anymore; it’s about building a better, more sustainable future for the entire industry.

It turns out that the most powerful thing you can build isn’t always something you can touch.

Does the idea of a “living” digital model of something as immense as an engine inspire you, or does it feel a little too much like something out of science fiction?

0 Comments